Having another go with my Clevedon Pier photograph. This time I used a thinner application of oil for the sky and less etching time. The sky has come out much better, but the shorter etch time wasn’t long enough to allow me to make a decent print. So, I’ll have another go, this time withContinue reading “Another step in my etching eduction”

Tag Archives: aluminium

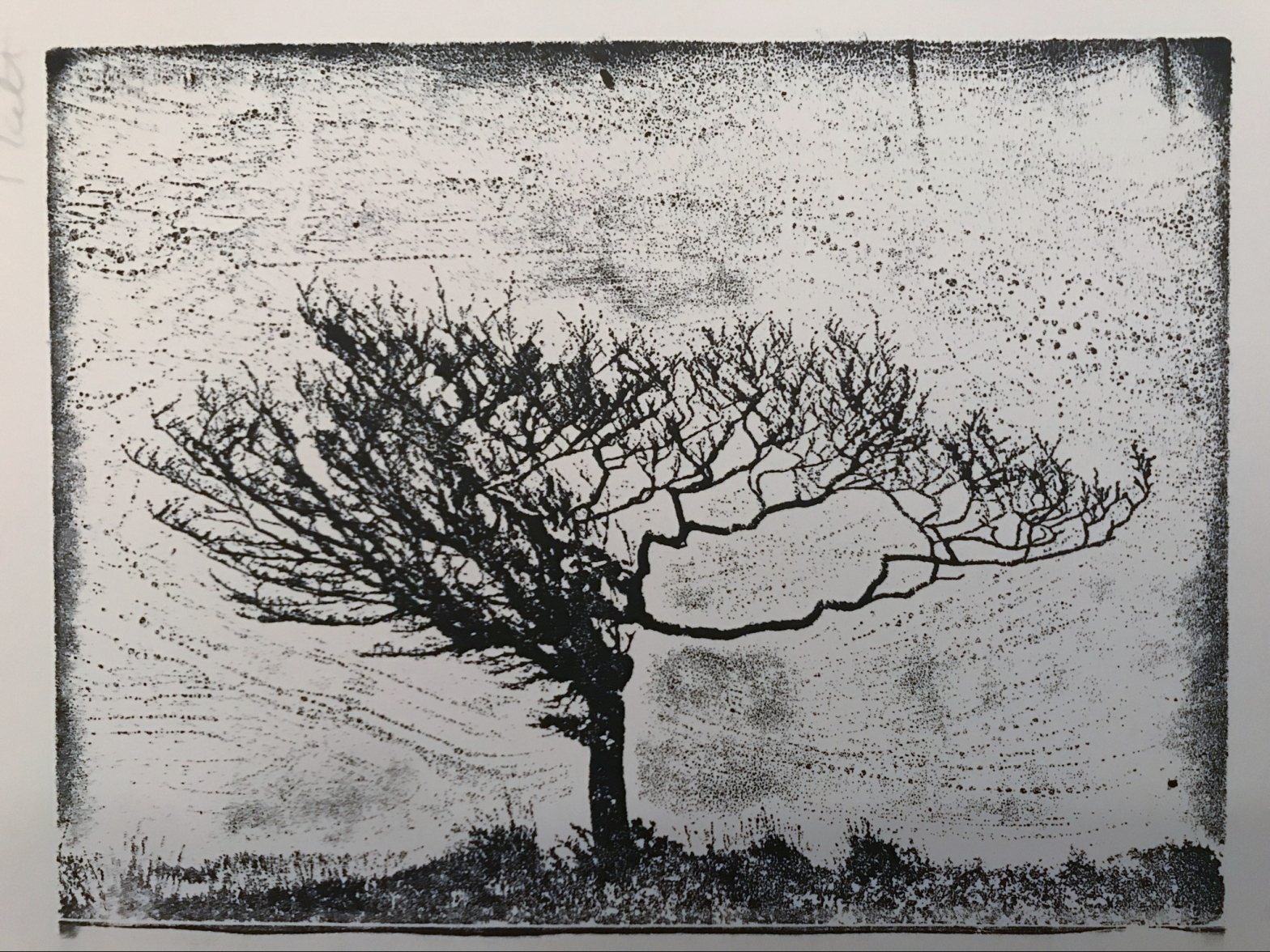

Progress with etching – Exmoor tree project

After my initial experiments with the etching process, I started today to apply what I have learned to my Exmoor tree images. (See previous etching blog for my first steps in this process). I opened one of my images into Photoshop, increased the contrast, applied the “Posterise” function and then deleted the background elements IContinue reading “Progress with etching – Exmoor tree project”

Photo-Print-Transfer-Etch-Print!

Today was bringing together my photography and my relief printing. Starting with a B&W photo with a lot of contrast – An old oak door in Ludlow, Shropshire: Resized to 150mm on the longest edge to fit my aluminium sheet and printed on a laser printer onto glossy inkjet paper. Next cut the paper toContinue reading “Photo-Print-Transfer-Etch-Print!”